Power

Arc Ignitions

Precision

Performance for

1, 2, 3, 4, 6 & 8 Cylinder

Engines

|

|

|

Power

Arc Ignitions

Precision

Performance for

1, 2, 3, 4, 6 & 8 Cylinder

Engines

|

SPARK PLUG & WIRE SPECIFICATIONS

|

WARNING:

Use only resistor core spark plug wires or Power Arc approved

spiral wires of at least 1000 ohms with all Power Arc Ignitions.

Use resistor spark plugs with all electronic ignitions to limit

the conducted EMI noise and radiated RFI noise.

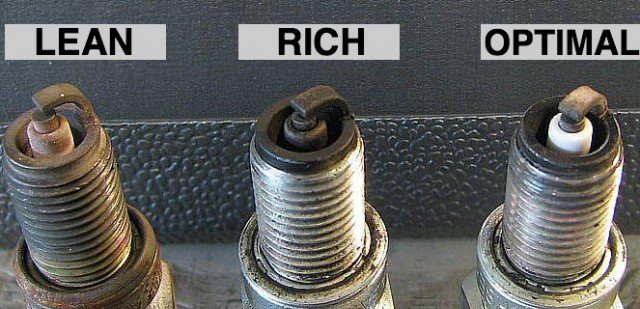

Initial suggested settings for spark plug gaps are: Single plug 0.028-0.032" Dual plug 0.025-0.030" These are maximum settings, go down from here Spark plug gap should be made as small as possible, while still maintaining performance. A wide spark plug gap can cause hard cold starting, misfires during rich or lean fuel conditions, and reduction of upper rpm range. To maintain a good secondary spark (multiple spark) within a wider rpm range it is wise to run a narrower spark plug gap. It is better to precisely place two stable, consistent sparks than to fire one wider spark that may cause misfires under various conditions. Many things effect spark plug gap settings: Compression Ratio: The higher the engine compression, the more voltage required to fire the plug, and the narrower the plug gap should be. RPM: The higher the rpm's the less time the coil has to charge to break over voltage or complete saturation. A narrower spark plug gap will help high rpm stability. Spark plugs with large side electrodes (ground straps) or spark plugs with split side electrodes are not recommended, they interfere with the flame front at the point of ignition. Coil choice, fuel flow, intake velocities & fuel temperature are but a few additional factors that can effect spark plug gap. Spark Plug Choice In most cases, it is not until the engine is modified, or the compression is raised significantly, that stock ignition systems and spark plugs begin to show signs of being inadequate. At this point, a variety of factors determine which spark plug will be best suited for a particular configuration. In these modified engines, specific electrode/tip combinations, electrode materials and colder heat ranges can provide measurable gains in power. If your vehicle has had extensive modifications, it would be best to seek the advice of the manufacturer of your vehicle, the aftermarket supplier who manufactured your modifications, or your mechanic. Modifications that will typically not require specialized plugs (in most cases the factory installed plug will be more than adequate) include adding a free-flowing air filter, headers, mufflers and rear-end gears. Basically, any modification that does not alter the overall compression ratio will not usually necessitate changing plug types or heat ranges. Such minor modifications will not significantly increase the amount of heat in the combustion chamber, hence, a plug change is probably not warranted. However, when compression is raised, along with the added power comes added heat. Since spark plugs must remove heat and a modified engine makes more heat, the spark plug must remove more heat. A colder heat range spark plug must be selected and plug gaps should be reduced to ensure proper ignition in a dense air/fuel mixture. Frequently Asked Questions Q: Why should I use a resistor spark plugs & spark plug wires? A: "R" or resistor spark plugs use a 5k ohm ceramic resistor in the spark plug to suppress ignition noise generated during sparking. You must use resistor spark plugs & wires in any vehicle that uses electronic ignitions or on-board computer systems to monitor or control engine performance. This is because resistor spark plugs & wires reduce (EMI) electromagnetic interference with on-board electronics. They are also recommended on any vehicle that has other on-board electronic systems such as engine-management computers, two-way radios, GPS systems, or whenever recommended by the manufacturer. In fact, using a non-resistor plug or low resistance spiral wound spark plug wire in most applications may actually cause the engine to suffer undesirable side effects such as an erratic idle, high-rpm misfire, engine run-on, power drop off at certain rpm levels, abnormal combustion and probable damage to the ignition and/or ignition coil. Q: Why are there different heat ranges? A: It is a common misconception that spark plugs create heat. They don't. A heat range refers to how much heat a spark plug is capable of removing from the combustion chamber. Selecting a spark plug with the proper heat range will insure that the tip will maintain a temperature high enough to prevent fouling yet be cool enough to prevent pre-ignition. While there are many things that can cause pre-ignition, selecting a spark plug in the proper heat range will ensure that the spark plug itself is not a hot spot source. Spark Plug Problem Diagnosis

Spark Plug Wires

Choice of spark plug wires is an important consideration when using an electronic ignition system. Electronic ignitions utilize IC's (integrated circuits) in there design for counting & timing purposes. These IC's, contrary to most thinking, are not effected by RFI (Radio Frequency Interference) noise generated by the high voltage breakdown of coils, producing the ignition spark. They are effected by the conducted EMI (Electro Magnetic Interference) passed to the ground plane and adjacent wires of the motorcycle via the spark plug wires & plug. The most effective way to limit the current produced in the secondary of the coil is to use carbon core resistor plug wires. Solid core wires and many spiral wound wires will not suppress this conducted EMI noise. Use only Power Arc approved spiral core wires and never use solid core wires. |

|

|